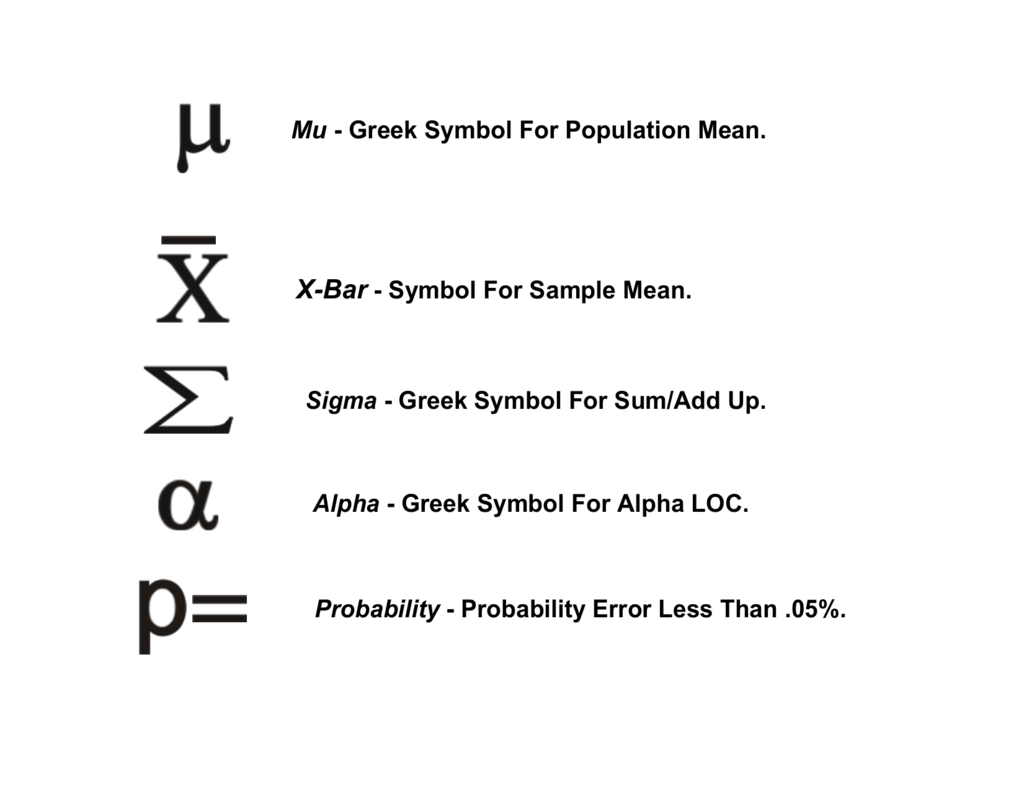

The two charts differ in how they track the within subgroup variation. So, the X chart monitors how the subgroup averages vary over time – this is why it is said to track the between subgroup variation. This is repeated and the X values are plotted over time. Where X i is are the individual X results in the subgroup. The average of each subgroup is calculated using the following: In this case, the subgroup size, n, is 5. You take those 5 weights and form a subgroup. You are measuring the weight for 5 consecutive bags at the start of each hour. For example, suppose you are tracking the weight of bags containing sand. You start with the individual values and then form subgroups of size n. Each is really two charts – one to track the between subgroup variation and the other to track the within subgroup variation. These two control charts are quite similar.

#Xbar means pdf

You may also download a pdf copy of this publication at this link.

The data used in the control chart figures below are also included in the workbook. This workbook contains the results of the simulation as well as the VBA code to let you run your own simulations. You may download the workbook with the simulation at this link. Estimating Sigma, the Process Standard Deviation.When to Use the X-R and X-s Control Charts Historically.The basic conclusion is that there is no reason not to use the X-s chart all the time. A simulation was developed to help do this. For the purposes of this publication, the chart to use is the one that gives you the best estimate of the process standard deviation. Traditionally, it has been suggested that you use the X-R chart with subgroup sizes of 9 or less you use the X-s chart with subgroup sizes larger than 9. In this publication, we will compare the two charts to see when you use one or the other. This chart is similar to the X-R chart, except that the subgroup standard deviation is used instead of the subgroup range for the within subgroup variation. There were a number of control charts I was exposed to back then. We definitely tried to keep things simple.

#Xbar means manual

There is still something to be said for teaching control charts using this manual method. The control charts we did back then were done manually – doing the calculations using a calculator and manually plotting the points, averages, and control limits. This was some years ago – back in the early 1980s. When I was first introduced to control charts, the X-R chart was used the most. Select this link for information on the SPC for Excel software.) Select "Return to Categories" to go to the page with all publications sorted by category. (Note: all the previous publications in the variable control charts category are listed on the right-hand side.

0 kommentar(er)

0 kommentar(er)